If you own an MGB that hasn't had its sills replaced, there's a good chance that it either needs them now or will at some point in the future. The purpose of this document is to introduce you to the MGB sill structure, explain why and how it rusts, answer some basic questions about sill replacement, and provide some resources for additional information.

MGB Sill Section - Common Questions:

Q: What are we talking about?

A: MGB sills are the structural components that connect the front and rear structure of the car. They're made up of several stamped sheet metal parts, welded together with spot welds.

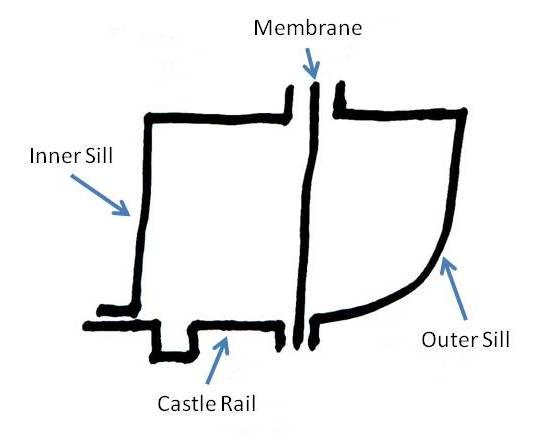

Referring to the following diagram, those parts are:

- The Inner Sill, or Inner Side Member - this is the part of the sill you see from the inside of the car.

- The Castle Rail. You can see this part from below the car.

- The Membrane, or Inner Panel is a simple generally flat piece of steel embossed with a triangular pattern.

- The Outer Sill, or Rocker, is what you see from the outside of the car.

MGB Sill Box - Cross Section Diagram. The magic that gives the monocoque chassis its stiffness.

The sill section extends from the rear of the front wheel well (underneath the front fender), underneath the door, extending under the rear fender to the front of the rear wheel well. Structurally, the inner sill, membrane, and castle rail form a closed box, or beam, that is highly resistant to bending. This gives the car longitudinal strength, so that if two adults are in the car, it doesn't fold in half. The sills tie into the cross-member, the floors, the dash panels, the a and b-pillars, and the rear rails, joining many of the structural components of the car together.

Q: How do I know if my sills are good?

A: Look for rust. MGB sills are prone to rusting, and for various reasons. The #1 issue is that the gap between the outer sill and the portions of the front and rear fenders that cover it is very small, maybe 1/16 of an inch. Over time, dust and dirt gets trapped in that gap, gets wet from condensation, and rust proceeds outward through the fender, and inward through the outer sill. Once the outer sill is penetrated, it keeps rusting, eventually eating through the membrane and castle rail. This rust is first visible as "surface rust" (which, of course, it isn't) bubbles low on the fenders, just ahead or behind (the "dogleg" area) the door.

The second issue is that water gets trapped under the carpets and rubber mats covering the inner sill, and begins to rust the inner sill (and floors) from the inside of the car out. New MGB owners have sometimes been shocked when they pull up these coverings, to find out what lies underneath.

The third issue is that the sill parts have only a light coating of primer, if that. The parts get wet, primarily through condensation, and rust begins. Cars driven in desert climates generally resist this issue the longest, but even they can show up with rust eventually.

Q: If they're bad, can they be fixed?

A: Absolutely. MGB's are still plentiful on the roads, and one of the benefits of that plenty is that there are still parts readily, and relatively inexpensively, available. It's just a "simple" matter of removing the bad parts, and installing good ones.

Q: If they're bad, do I need to fix them?

A: Depends. Depends on how bad they are, what your plans are for the car, and lots of other factors. MGB's have been driven thousands of miles over many years with rusty sills.

It also depends on how much money you want to put into the car, what other work it may need, etc. Generally it's VERY easy to spend more on these cars than they are worth, and replacing sills is one of the more expensive repair jobs to perform on an MGB. You likely can't justify it as an investment, if you're honest with yourself, but it's easy to justify if you're emotionally attached to the car, or want to learn new skills on an inexpensive platform, or just want an excuse to collect a new set of tools.

Q: I want/need to fix my sills. Should I fix them, or hire someone to do it?

A: Another question that will 'depend'. How much time do you have? How much money? What skills do you have? What interest and aptitude do you have to learn new skills? Do you have a workspace? Do you live with someone who thinks that 'workspace' is really their parking space?

Those who hire someone to do it generally have much more money than time available to them, but if you don't have a workspace, or don't trust yourself to do the job, those are good reasons as well. Those who do it themselves have someplace to do the work, and either already have the skills and tools, or are confident they can obtain them from friends, schools, or picking them up on their own. When they're done, they have the peace of mind from knowing exactly how it was done, and how well.

Q: What parts should I use?

A: Get the best possible parts. There are generally three choices:

- British Motor Heritage (BMH) parts are considered the best you can get. Often they are made with original tooling, or the parts at least match those that go into new MGB body shells that are still being produced. You'll pay more for BMH parts, and likely save time as a result.

- Steelcraft parts are another option, they're made from tooling intended to make replacement parts. There have been some complaints about their fits at times, but many MGB repair jobs have been made with them. Less expensive, but you may spend a lot more time and effort getting them to fit.

- Last are non-branded parts – the supplier can't tell you who made them or where. Avoid them.

Please refer to the Link Directory for recommended parts suppliers.

Q: What skills will I need?

A: You'll need to know how to:

- Weld. These jobs are generally done with a MIG welder. You can learn to weld by teaching yourself, having a buddy teach you, or attending a welding class at a local technical or vocational school. Google "learn to MIG weld" and you'll find a number of web sites with instructional materials available, many from MIG welder manufacturers.

- Remove spot welds. The rusted out sill parts that you'll need to replace have to be physically removed from the car, and they weren't bolted in. They were spot welded. Many times. So you'll need to get good at finding and removing spot welds. This can be done by drilling them out, either with standard drill bits or with specific spot weld removal bits, or by grinding them out.

- Make patches in sheet metal. While much of the new metal you'll be replacing will be in the form of replacement panels, you'll invariably find that the parts that they join to have localized rust damage. Many times the quickest and cheapest way to fix that damage is by making up a sheet metal patch and welding it in. Patches can be made out of new sheetmetal of the correct thickness, out of scrap metal from your car, from a part cut off of a donor car, or from a part cut off a replacement panel. This is where you really get into creative problem solving.

Q: What tools will I need?

- A MIG welder. These are relatively inexpensive welders, available from welding supply stores, home centers (Lowe's, Home Depot) and multiple mail order tool suppliers. Good ones can also be found on Craig's List. A unit that runs off of 110v, and uses shielding gas, can handle this job. Along with the MIG welder, you'll need a gas cylinder (rented or bought), a cart for the welder and cylinder, and, most importantly, an auto-darkening helmet. This helmet will enable you to see while you're setting up to weld, and instantly darken when you begin to weld so that you can continue to see while the weld is forming. Don't try to learn to weld without one.

- A drill, drill bits, angle grinder (4 to 4.5"), grinding wheels and cut-off wheels, hammers, and a tool to separate panels (an old butcher knife works well) are all handy in removing parts/panels. You can probably justify getting a Drill Doctor to sharpen bits, for the cost of the bits that you won't have to buy.

- Clamps of various shapes/sizes for holding parts in place while you weld them. Harbor Freight is a good source for cheap vice-grip type clamps – buy them as you need them. Sheet metal screws and Clecko clamps are also handy for holding parts in position for checking panel fits and gaps before welding. Measuring and marking tools are also handy during the welding stage.

- The normal assortment of hand tools, along with a workbench and vice are good to have.

Q: If I fix them, how do I do it?

A: Since almost every MGB will need this job at some point, there were 500k of them built, and the newest is over 30 years old, a LOT of MGB sill replacement have been done. Many of them have been documented in various forms, so there is a lot of reference material to use.

Keep in mind that no two sill repair jobs are identical. The set of parts that must be replaced, and the rust damage to related parts, varies from job to job. If you've never done this kind of work before, it's best to get familiar with as many jobs as possible, so you'll be familiar with the ones that best match the job you'll need to do on your car. You can't be too prepared, or know too much.

[Ed. Note - it doesn't hurt to practice your welding skills on scrap metal before diving into your car either!]

Information Resources:

Books – "MGB Restoration Manual", by Lindsay Porter

Published by Haynes in 1992, this book has been updated and revised at least 11 times. It is, itself, an updated version of Porter's "Guide To Purchase & DIY Restoration Of The MGB", which was published in 1982. Both books are good, and have chapters on sill replacement, however don't expect them to cover the topic in the kind of detail you'll need if you've never done this job before. They give a good overview of the process, and can be good inspiration, however.

The books are available in the MG Experience Bookstore

Web – Middlebank

This site provides a good overview of both sill replacement and other typical MGB body panel replacement jobs.

Web – Chicago MGB Club

The Chicagoland MG Club has a good site with a lot of MGB information, including articles on several sill jobs. The most recent is at:

Web – Lee Miller's Project Pages

Lee's done a couple of cars, and has documented them well at his site. He also has many of these links at his site as well.

http://www.miller-garage.com/modules.php?name=News&file=article&sid=10

Web – Peter Plouf's Cardomain site

Peter has a great deal of experience with body work on British sports cars, and has documented several of his projects on the Cardomain site – including two MGB sill jobs:

Web – Phantomracer's Site

Mr. Phantom documented his sill job at this site:

Streaming Video – "An MG Is Born"

This is a 10 part series produced for the British Discovery Channel that follows the reconstruction of an MGB. Episode 3 focuses in on the sill replacement, but there's a lot of good rust repair/body work content spread throughout the series.

You can find this video by searching YouTube for "An MG Is Born".

Web – MG Experience Journals

There are hundreds of Owners Journals documented on the MG Experience site. Many of them deal with sill replacement projects.

These were my attempts to document the sill job I did on my 1972 MGB Roadster:

Sill Removal

http://www.mgexp.com/journal/Steve+Lyle/2698

http://www.mgexp.com/journal/Steve+Lyle/3376

http://www.mgexp.com/journal/Steve+Lyle/3729

Sill Installation

Web – The MG Experience MGB and GT Forum

No matter how much you study, practice, and prepare, you'll have questions. The MG Experience MGB and GT Forum, is like a room full of people, some of whom have probably experienced the problem you're dealing with or have the answer to your question. Just walk in, ask your question, and you'll be amazed at how much assistance will be available to you.

You can also search the forum archives for answers to particular questions or information on specific topics. Just give some thought to the terms to search for, and you'll have access to years of experience.

Want to leave a comment or ask the owner a question?

Sign in or register a new account — it's free