In order to keep damper oil in the piston, there's an o-ring that needs to be replaced. The needle assembly is held in the piston by a star washer. Many people just say push the star washer through the body of the piston using a drift with oil in the tube (which can cause scoring on the piston), but here's a method that works perfectly without risking damage to the piston.

- Remove the piston from the carburetor, and remove the diaphragm.

- Remove the retaining screw on the side of the piston, the one keeping the needle from turning, and then using your Zenith adjusting tool, completely remove the needle.

- Turn the carb over so the "needle holder" is up. Take a soft drift and tap the holder in about 1/8" inch.

- Turn the piston back over, so you have it up like it's sits in the carb. Take your Zenith adjusting tool and push the needle assembly back down. What you've done is put a gap between the needle holder and the star washer.

- Take a small pick or a bent piece of wire, and reach down the tube, catching the outside of the star washer. It will flip over on its side and you can turn the piston over - it will fall out.

- Now you can push the "needle holder assembly" up through the tube in the piston, and you'll see the o-ring you need to renew - it will probably be hard as a rock.

Reassembly is just reverse - once the needle holder is pushed back to the bottom of the tube, drop the star washer back down the tube, and shake it a bit. Take a drift or small dowel and push the star washer back down onto the assembly. Put the needle back in, reinstall the screw that keeps it from turning (be sure it goes into the slot in the needle), and you're done.

The great thing about this method is you don't get any piston scoring.

Notice how far the needle is in or out of the piston before you take it apart, so you can set it back like it was when you reassemble. Also, look for flat spots on the needle - if there are any, then get a new needle.

Just in case you didn't know, the needle is biased, or "spring loaded" so it suppose to sit at an angle.

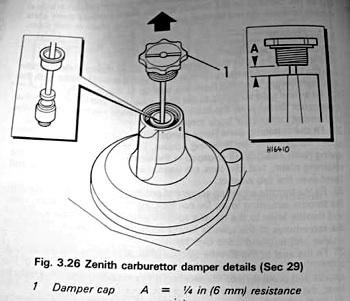

It will help if you look at the picture in your workshop manual or the Moss catalog while you're reading this.

This method was provided to me by Fletcher Millmore.

Also how about the by-pass valve, I am going to put a new diaphragm kit in it. Are there any on-line instructions?

Want to leave a comment or ask the owner a question?

Sign in or register a new account — it's free