MGA Forum

1800 3-main engine rebuild

Posted by redmga57

|

redmga57

Russ Hulting

|

Topic Creator (OP)

Nov 23, 2014 12:09 PM

Joined 12 years ago

8 Posts

|

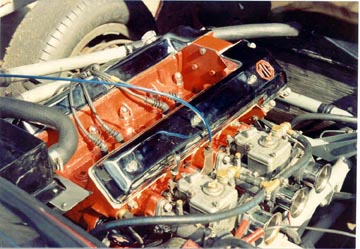

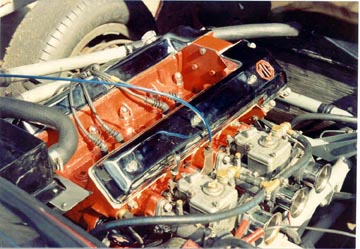

Last winter I rebuilt my 3-main 1800 in my MGA. I installed new pistons and rings, std new cam, new cam bearings, crank was ground .10, new bearings, engine was bored by my machine shop .20. New pistons were at the machine shop, so he could measure and bore the cylinders to fit the pistons. The head was machined with new seats. We used the existing valves and guides, as they appeared to be fairly new from a previous rebuild. The guides are the bronze guides. The machine shop did their work, and I assembled the engine in my shop. We used existing springs, probably should have used new ones.

The first 200 miles was great. At that time I developed a ticking noise in the engine. I check the usual sources for the noise. Checked valve lash, installed new exhaust manifold gasket, new exhaust donut, as I thought it could be an exhaust leak.

As I needed a new winter project, I pulled the engine this week and tore the engine apart. I haven't found the source of the ticking noise, but when I dropped the pan, I noticed small pieces of aluminum at the bottom of the pan at the screen. I removed the pistons and piston #4 is scuffed and the cylinder wall is also scuffed.

What do I need to do here? Do I buy a new piston and have the machine shop rebore? Do you think this a problem caused by a wrong bore size, or a piston problem?

Then my original problem, which is the ticking sound. Could this be caused by a sticking valve sliding in the guide. I have read that with the bronze guide tolerances are critical. The ticking sound goes away at 2300 RPM. I hear it at idle and when under load.

I enjoy working on my own car and sometimes it takes a second time to get it right. I'm not building a race engine, just a dependable engine

Any help is appreciated.

Russ

The first 200 miles was great. At that time I developed a ticking noise in the engine. I check the usual sources for the noise. Checked valve lash, installed new exhaust manifold gasket, new exhaust donut, as I thought it could be an exhaust leak.

As I needed a new winter project, I pulled the engine this week and tore the engine apart. I haven't found the source of the ticking noise, but when I dropped the pan, I noticed small pieces of aluminum at the bottom of the pan at the screen. I removed the pistons and piston #4 is scuffed and the cylinder wall is also scuffed.

What do I need to do here? Do I buy a new piston and have the machine shop rebore? Do you think this a problem caused by a wrong bore size, or a piston problem?

Then my original problem, which is the ticking sound. Could this be caused by a sticking valve sliding in the guide. I have read that with the bronze guide tolerances are critical. The ticking sound goes away at 2300 RPM. I hear it at idle and when under load.

I enjoy working on my own car and sometimes it takes a second time to get it right. I'm not building a race engine, just a dependable engine

Any help is appreciated.

Russ

|

jdtaylor014

Joel Taylor

|

Nov 23, 2014 12:26 PM

Joined 13 years ago

54 Posts

|

Saw this on a Lotus 907 engine in a friends Jensen-Healy. Worth checking. https://www.hastingsmfg.com/ServiceTips/piston_cylinder_scuffing.htm Other causes are too much heat in the combustion chamber, think lean condition and/or ignition. Lack of lubrication, check pump and screen, skirts are splash lubricated so flow is essential. Proper sizing of bore to piston. Follow piston manufacturer recommendations. Cast, forged and hypereutectic pistons all have different expansion characteristics and must be accounted for with bore sizing. Check wrist pins for binding.

Edited 1 time(s). Last edit at 2014-11-23 12:41 PM by jdtaylor014.

Edited 1 time(s). Last edit at 2014-11-23 12:41 PM by jdtaylor014.

|

|

Nov 23, 2014 01:07 PM

Top Contributor

Joined 18 years ago

3,062 Posts

|

|

Nov 23, 2014 02:49 PM

Top Contributor

Joined 10 years ago

1,128 Posts

|

|

In reply to # 2857263 by joemamma

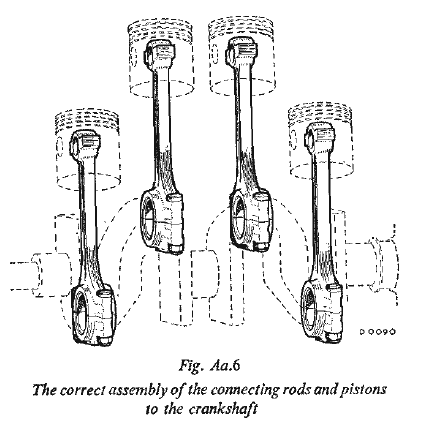

3 main MGB engines have off set con rods. Any chance you have the rods in the wrong journals on the crankshaft?

Took the words out of my mouth. I don't know if they will physically go in but that scuff is not on the thrust face of the piston, the piston is a few thou smaller at that point so it should not touch the cylinder walls. Take the piston off the rod and see if the small end of the rod was rubbing on the side of the pin boss.

|

redmga57

Russ Hulting

|

Topic Creator (OP)

Nov 23, 2014 05:30 PM

Joined 12 years ago

8 Posts

|

|

redmga57

Russ Hulting

|

Topic Creator (OP)

Nov 23, 2014 07:04 PM

Joined 12 years ago

8 Posts

|

|

|

Nov 24, 2014 05:35 AM

Top Contributor

Joined 18 years ago

43,753 Posts

|

In reply to # 2857385 by redmga57

I just checked, and the #2 and #3 are offset in and #1 and #4 are offset out. I have them in the correct cylinder hole

Thanks

Thanks

You could not have got everything to bolt up if you the offsets were wrong anyway. If the offset were wrong, the top section of the rod (attached to the piston) would not matched up with the crank's rod journals center line, in short it would impossible to do this. Hard to say why that did happen, I notice it was starting to happen on the piston lying to the right of the worse one. my guess would be too tight of cylinder bore to piston clearance, the only other thing that could have caused that was if the engine got really hot.

Here's picture of how the rod offset's go, this is from the factory 1275 manual, but all the MG offset rods go in the same orientation.

Hap Waldrop

Acme Speed Shop

864-370-3000

Website: www.acmespeedshop.com

hapwaldrop@acmespeedshop.com

Edited 1 time(s). Last edit at 2014-11-24 05:37 AM by Speedracer.

Member Services:

MG/ Triumph Performance Street Engines -

Cylinder Head Porting for street performance and race -

DIY Engine Rebuild Kits With Free Tech Advice -

VTO alloy wheels for British Sports Cars, and others

|

Nov 24, 2014 10:14 AM

Top Contributor

Joined 19 years ago

17,982 Posts

|

|

Yeah, that has to be a clearance issue or an overheating thing, but you'd have noticed the latter.

IIRC the workshop manual calls for very tight piston to wall clearances. I increase them and have never had any problems.

Bill Spohn www.rhodo.citymax.com/carstuff.html

Current: 1958 MGA Twincam (race car (170 bhp)),1962 MGA Deluxe Coupe (98 bhp)

1957 Jamaican MGA (200 bhp)1965 1971 Jensen Interceptor (350 bhp)

2009 Pontiac Solstice GXP Coupe (375 bhp)

2007 BMW Z4M coupe (340 bhp)

Recent: 1969 MGC roadster (175 bhp),Jensen CV8 (375 bhp),

1969 Lamborghini Islero S (350 bhp), 1988 Fiero GT turbo (300 bhp)

North Vancouver BC

IIRC the workshop manual calls for very tight piston to wall clearances. I increase them and have never had any problems.

Bill Spohn www.rhodo.citymax.com/carstuff.html

Current: 1958 MGA Twincam (race car (170 bhp)),1962 MGA Deluxe Coupe (98 bhp)

1957 Jamaican MGA (200 bhp)1965 1971 Jensen Interceptor (350 bhp)

2009 Pontiac Solstice GXP Coupe (375 bhp)

2007 BMW Z4M coupe (340 bhp)

Recent: 1969 MGC roadster (175 bhp),Jensen CV8 (375 bhp),

1969 Lamborghini Islero S (350 bhp), 1988 Fiero GT turbo (300 bhp)

North Vancouver BC

|

redmga57

Russ Hulting

|

Topic Creator (OP)

Nov 24, 2014 07:30 PM

Joined 12 years ago

8 Posts

|

The engine has never been over 200, so I don't think it is a heat issue. We set the bore at the piston company's recommendation of .0025. I think I will take it back in to the machine shop and check the diameter and maybe open it up a little.

Thanks for your comments

Thanks for your comments

Forums

Having trouble posting or changing forum settings?

Read the Forum Help (FAQ) or contact the webmaster